KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Fall 2024 Vol. 23Development of a microbial process for producing jasmine fragrance

An efficient microbial process to produce benzyl acetate, a jasmine-scented compound, from glucose was developed by systems metabolic engineering and a delayed co-culture strategy.

Benzyl acetate, a compound known for its sweet aroma reminiscent of jasmine, is extensively used in the manufacture of cosmetics, food, and beverages. Traditionally, this compound is either extracted from flowers or chemically synthesized from petroleum derivatives. However, both methods present challenges—extraction from flowers is unable to meet the high global demand, and chemical synthesis is unsustainable due to its reliance on non-renewable petroleum and the consumer preference for ‘natural flavors’.

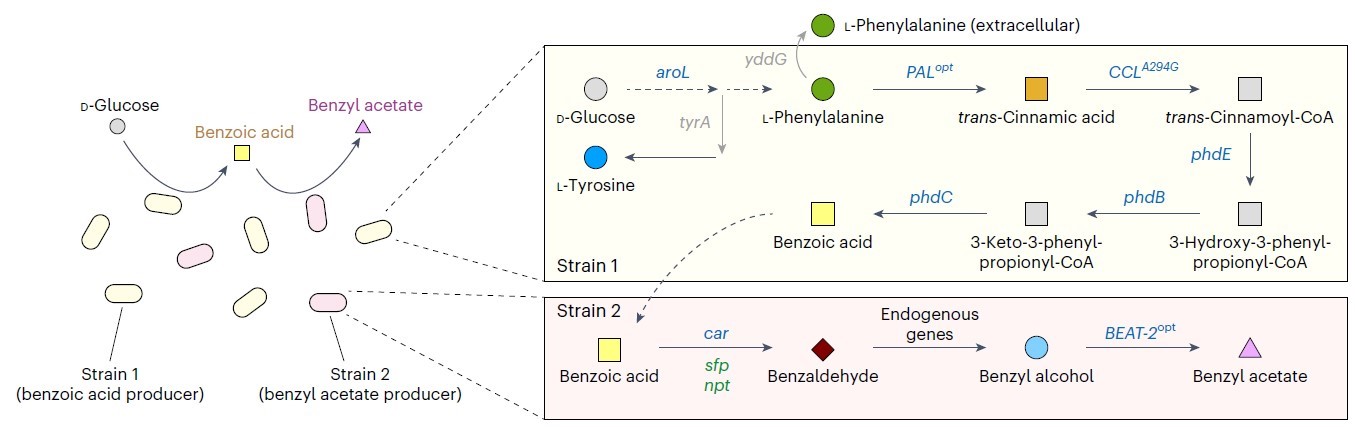

To address these issues, a research team led by distinguished professor Sang Yup Lee employed systems metabolic engineering to modify Escherichia coli to convert glucose, a renewable sugar, into benzyl acetate through benzoic acid as an intermediate compound, in an eco-friendly manner.

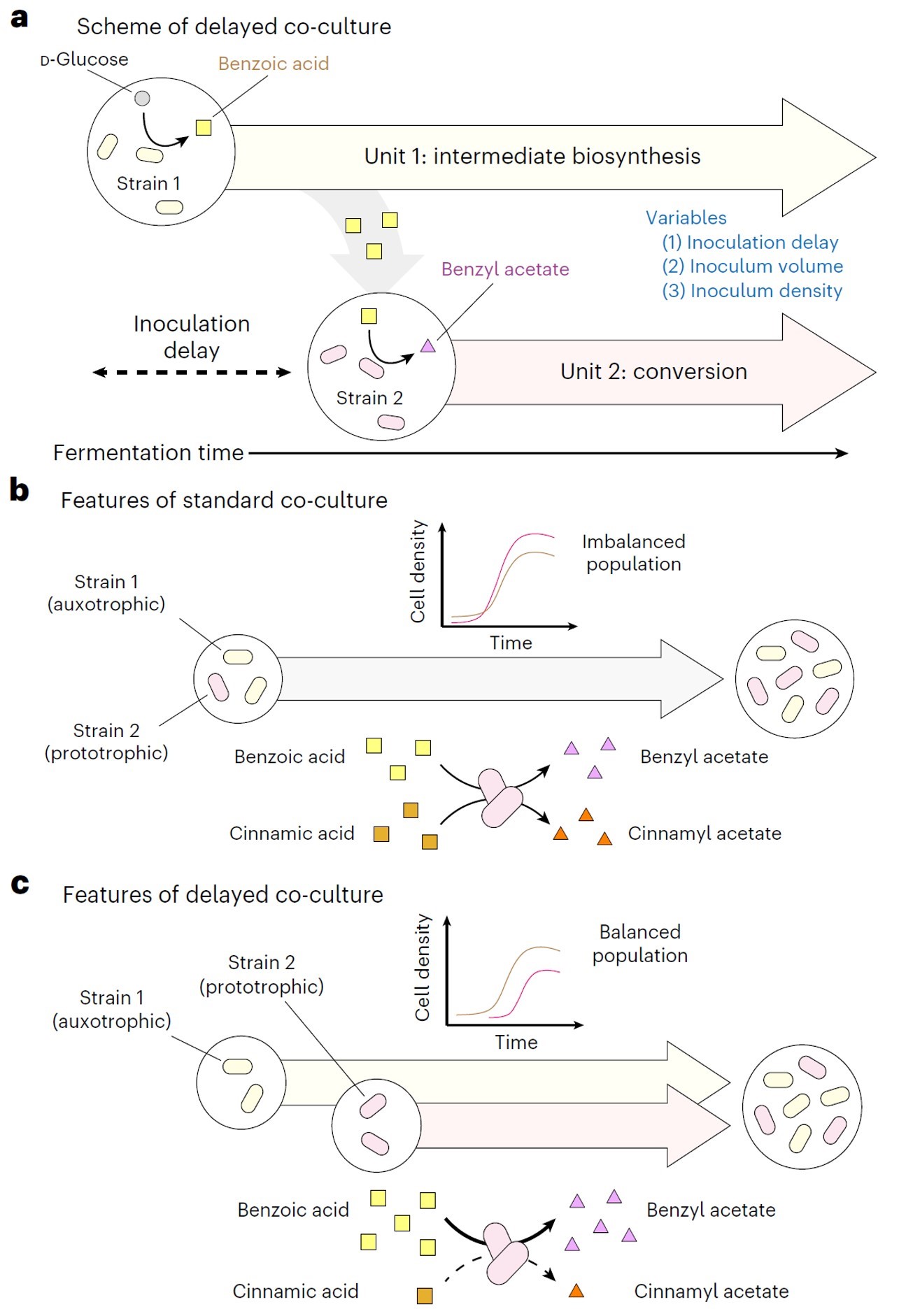

The research highlighted initial challenges related to enzyme promiscuity, which led to the formation of cinnamyl acetate as a byproduct. This challenge arose given that the enzyme used in converting benzoic acid to benzyl acetate also non-specifically interacts with other compounds present in the reaction mixture. To overcome this issue, the research team developed a 'delayed co-culture strategy' that effectively increases the yield of the desired product. The delayed co-culture strategy consists of two steps, the initial cultivation of a benzoic-acid-producing strain for the accumulation of benzoic acid, and the subsequent introduction of a second strain to transform the accumulated benzoic acid into benzyl acetate.

By applying the delayed co-culture strategy, the researchers were able to produce 2.2 g/L of benzyl acetate, representing a more than ten-fold enhancement, by suppressing the formation of byproducts. Furthermore, the potential for commercialization of the microbial process for the production of benzyl acetate was evaluated through a techno-economic analysis.

Research professor Kyeong Rok Choi, the first author of this study, noted that this work not only demonstrates a successful application of metabolic engineering to produce a commercially valuable chemical but also addresses common challenges in the field, such as the promiscuity of enzymes and byproduct formation.

Distinguished professor Sang Yup Lee said, "If we continue to increase the variety and number of microbial processes that can produce industrially useful chemical compounds in a sustainable manner, and also work on developing effective strategies to resolve the chronic and inevitable issues that arise during microbial strain development, the transition from the petrochemical industry to a more environmentally friendly and sustainable bioindustry will be realized."

This paper was published online on February 26 in 'Nature Chemical Engineering', a journal issued by Nature. (Paper title: A microbial process for the production of benzyl acetate)

This work was supported by the ‘Bio & Medical Technology Development Program (2021M3A9I4022740)’ of the National Research Foundation and funded by the Ministry of Science and ICT, Republic of Korea. This work was also supported by the ‘Cooperative Research Program for Agriculture Science and Technology Development (Project No. RS-2021-RD009210)’ of the Rural Development Administration, Republic of Korea.

Most Popular

High-performance and sustainable paper coating material that prevents microplastics

Read more

Next-generation ceramic electrochemical cells for global net-zero goals

Read more

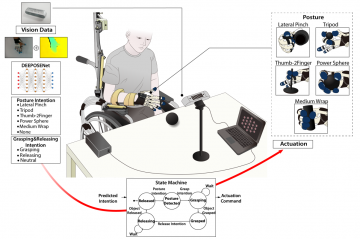

Multi-hand posture rehabilitation for stroke survivors: Rehabilitation system using vision-based intention recognition and a soft robotic glove

Read more

Impacts of new town developments on carbon sinks in the Seoul metropolitan area

Read more

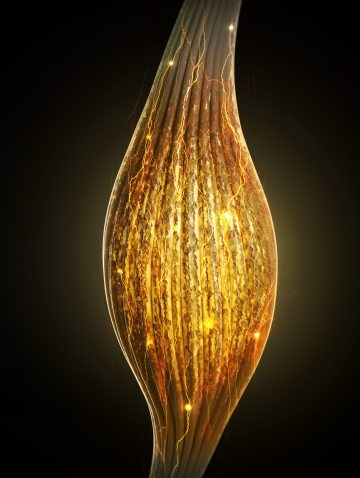

Revolutionizing strength: Hercules artificial muscles 17 times stronger than human muscles

Read more