KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2024 Vol. 22Electronics for next generation: Fabricating intrinsically stretchable devices using nanoscale dielectric

Creating intrinsically stretchable electronics with large-area uniformity, low power consumption, and performance comparable to rigid devices still remains challenging. A nanoscale stretchable dielectric developed in this study showed excellent electrical, mechanical and chemical properties and addressed all problems mentioned above.

Despite recent progress in materials and fabrication technologies, the development of intrinsically stretchable electronic devices equipped with large-area uniformity, low power consumption, and performance comparable to conventional rigid devices still remains a challenge. An important obstacle is the lack of an elastic dielectric material that can be both thin and uniform over extensive areas while providing robust insulating properties, as well as high mechanical and chemical stability. Therefore, the ideal stretchable dielectric material should meet specific requirements. First, it is essential for the deposition method to align with existing microfabrication processes and yield a film with large-area uniformity. To satisfy such requirements, a stretchable dielectric layer should possess exceptional chemical and thermal stabilities to guarantee its compatibility with the photolithography process. In addition, the dielectric thickness should be in nanoscale to enable precise electrical control of the channel with minimal gate biases. Lastly, the stretchable dielectric must show outstanding electrical and mechanical robustness to suppress gate leakage and withstand repeated mechanical deformations.

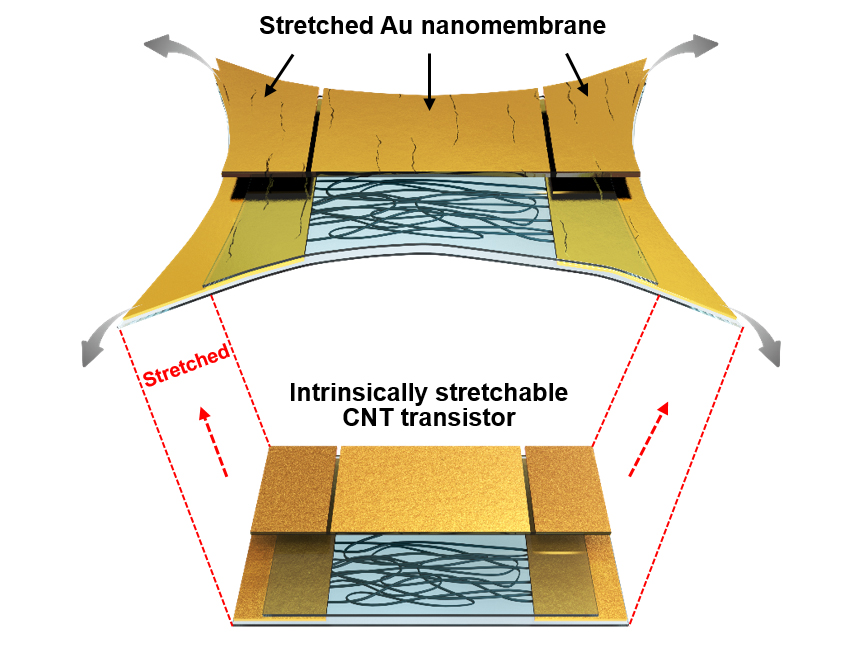

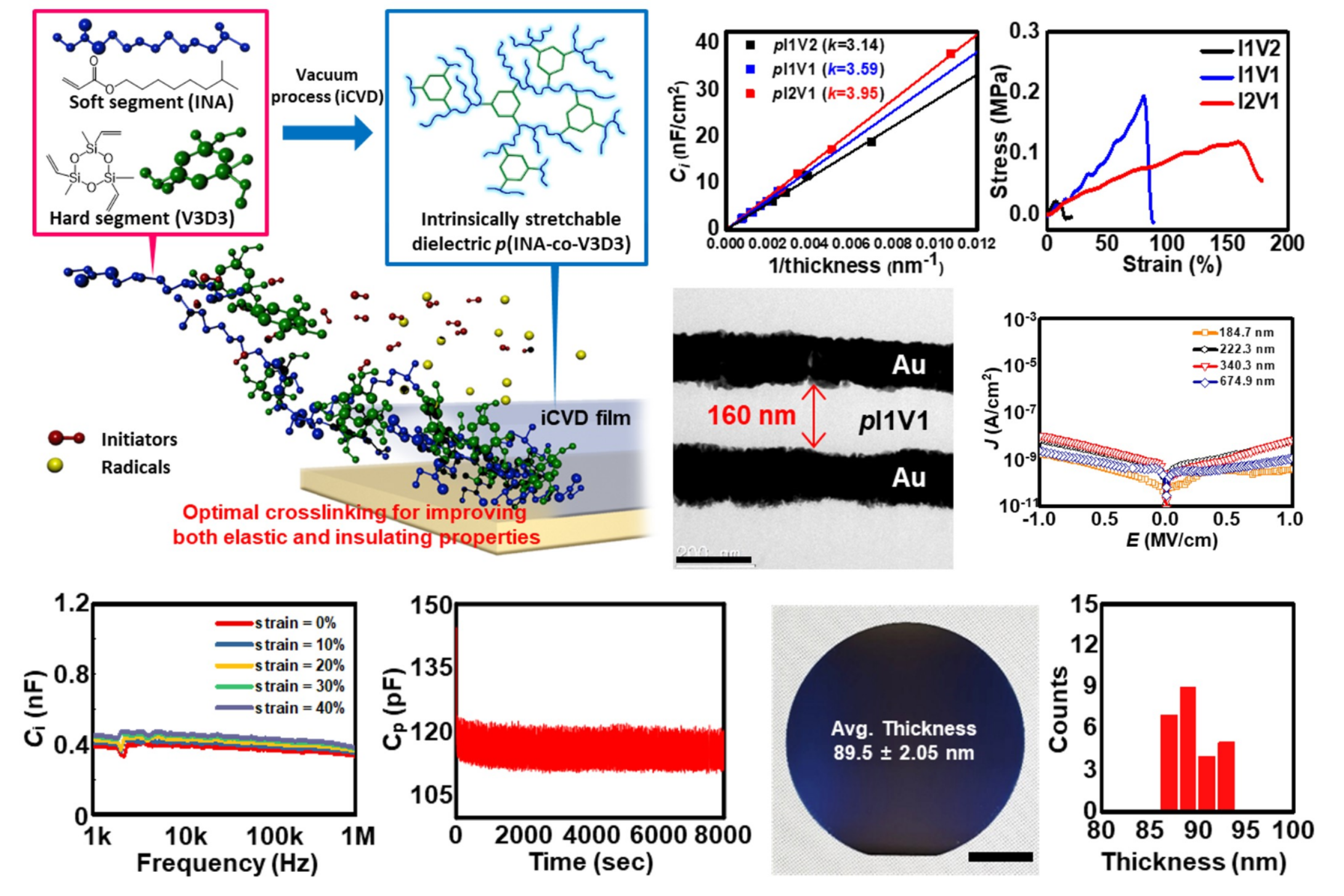

To meet these criteria, a research team under Professor Sung Gap Im in the Department of Chemical and Biomolecular Engineering at KAIST developed a high-performance ultrathin stretchable dielectric material, and realized wafer-scale stretchable devices in collaboration with Professor Dae-Hyeong Kim from Seoul National University and Professor Donghee Son from Sungkyunkwan University. The ultrathin stretchable dielectric was fabricated by copolymerizing isononyl acrylate (INA) and 1,3,5-trimethyl-1,3,5-trivinyl cyclotrisiloxane (V3D3) monomers through the initiated chemical vapor deposition (iCVD) process. In this process, INA served as a soft segment for stretchability, while V3D3 acted as a crosslinkable hard segment, imparting robust insulating properties (Figure 1).

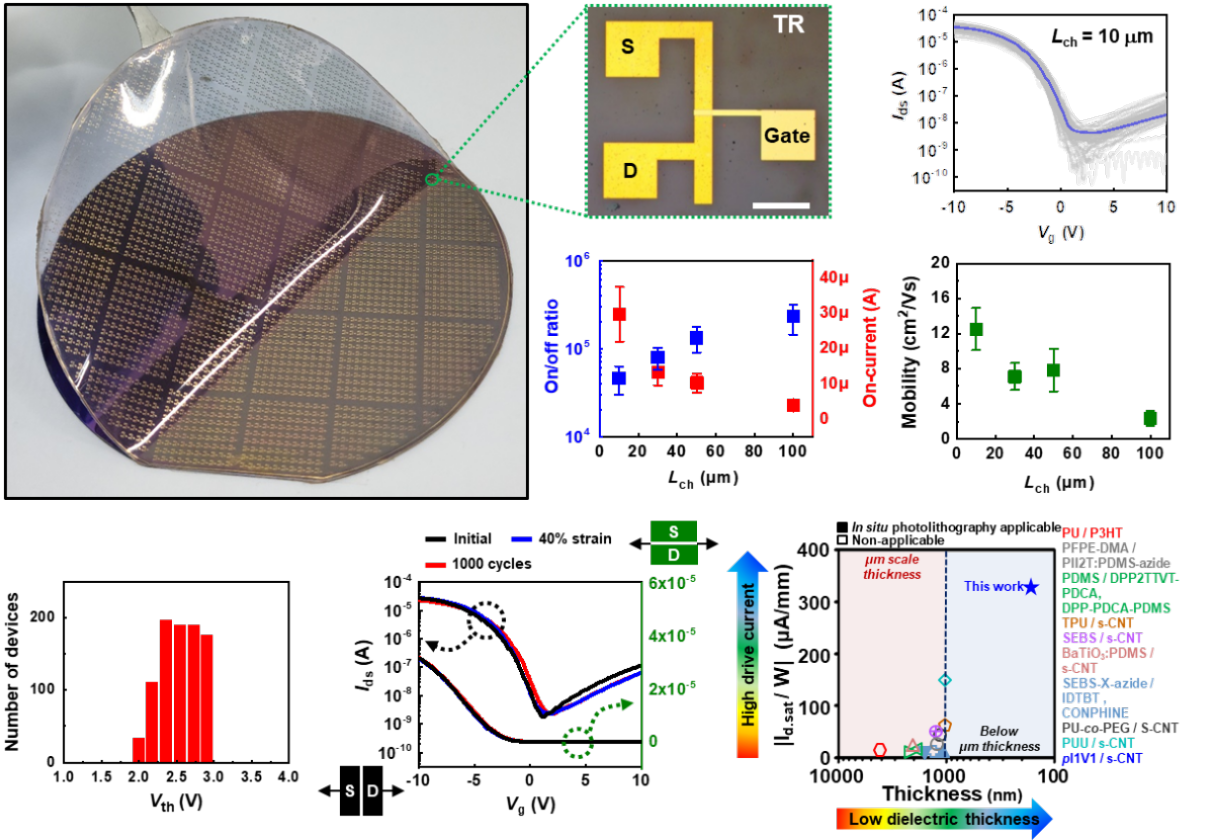

The copolymer film with an optimized composition, pI1V1, exhibited excellent chemical and thermal stability during microfabrication processes, superior insulating properties at the thicknesses of 200 nm and large-area uniformity (8-inch wafer scale). This enabled the realization of wafer-scale intrinsically stretchable transistors with nanoscale vacuum-deposited dielectric films, using semiconducting carbon nanotube networks as the channel material. These transistors showed low voltage operation and great electrical performance comparable to those using inorganic dielectrics like Al2O3, while retaining high stretchability (Figure 2). The device maintained stable performances after 1,000 stretching cycles at 40% strain. The research team also created advanced circuits like p-type inverters and logic gates that can operate effectively even with strains of up to 40% applied.

The high-performance stretchable ultrathin dielectric material and manufacturing technology introduced in this study are expected to become key source technologies that enable the realization of advanced next-generation artificial electronic skin and portable wearable applications through large-scale integration of low-power stretchable electronic systems in the future.

This study was published on February 02, 2023 in Nature Electronics under the title “A vacuum-deposited polymer dielectric for wafer-scale stretchable electronics” (Nature Electronics, 2023, 6.2: 137-145.)

* Figures were revised from the original manuscript. Copyright: 2023 Springer Nature

Most Popular

An intravenous needle that irreversibly softens upon insertion by body temperature

Read more

Consistent visual editing of complex visual modalities: videos and 3D scenes

Read more

SUPPORT enables accurate optical readout of voltage signals in neurons

Read more

AI for detecting aimbots in FPS games

Read more

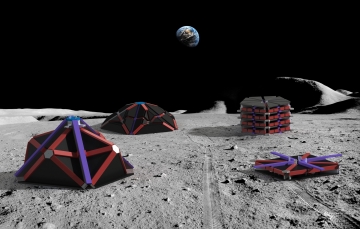

Origami-based deployable space shelter

Read more