KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

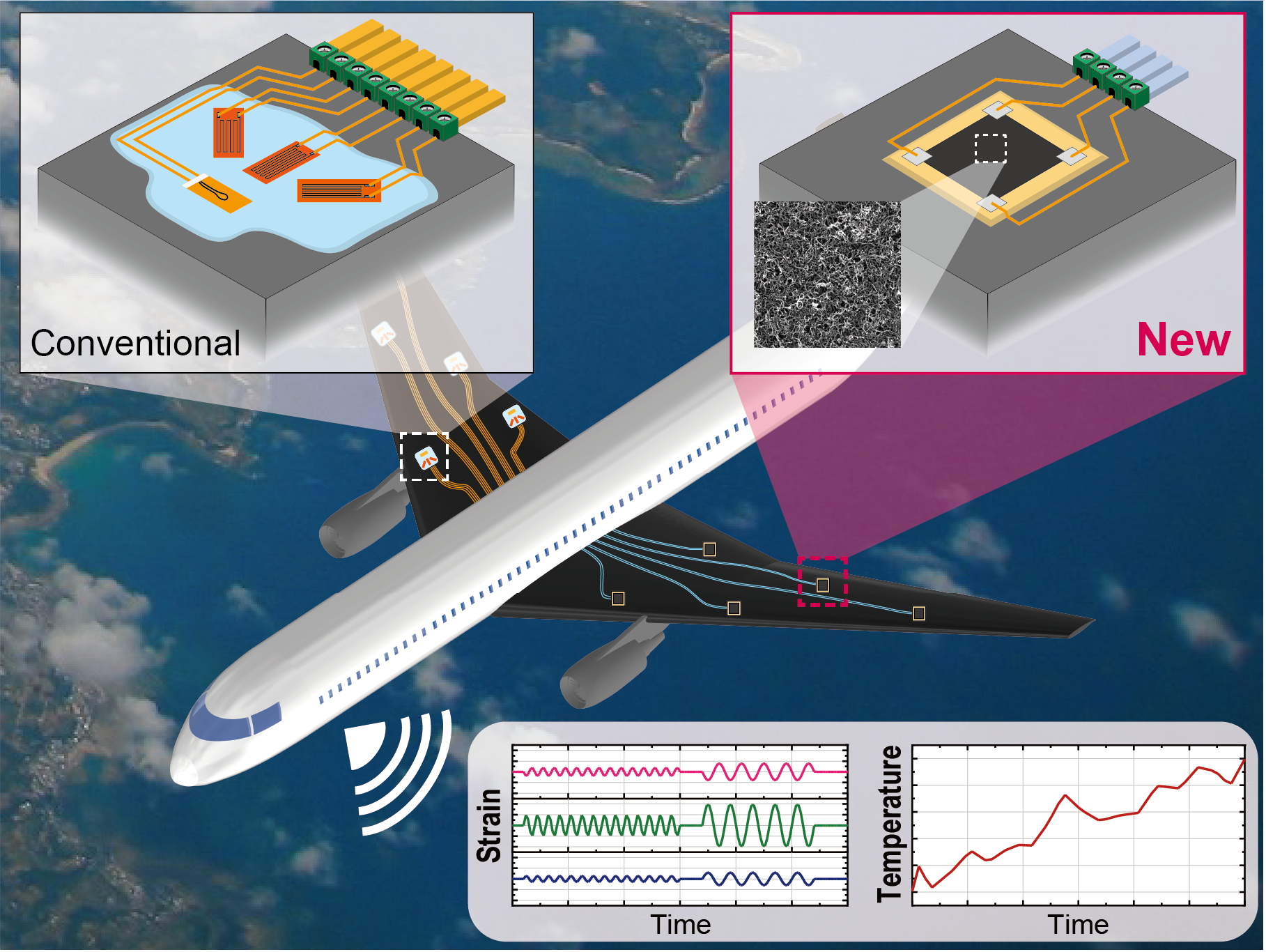

Fall 2024 Vol. 23Nanocomposite sensor system capable of simultaneous measurements of omnidirectional strain and temperature

A next-generation nanocomposite sensor system that simplifies conventional structural health monitoring systems has been developed. This system can monitor omnidirectional strain and temperature in real time with a single nanocomposite sensor, a task that requires at least four commercial sensors.

Structural health monitoring systems refer to a technology that collects and analyzes physical quantities measured by sensors integrated into structures to identify internal damage in real time. These systems are applied to ensure the sustainable operation of structures with high structural reliability and longevity requirements. In particular, structural health monitoring has become ever more crucial with regard to composite structures, which are increasingly utilized in various fields, including the aerospace field, due to the unpredictable failure mechanisms inherent in heterogeneous composite materials.

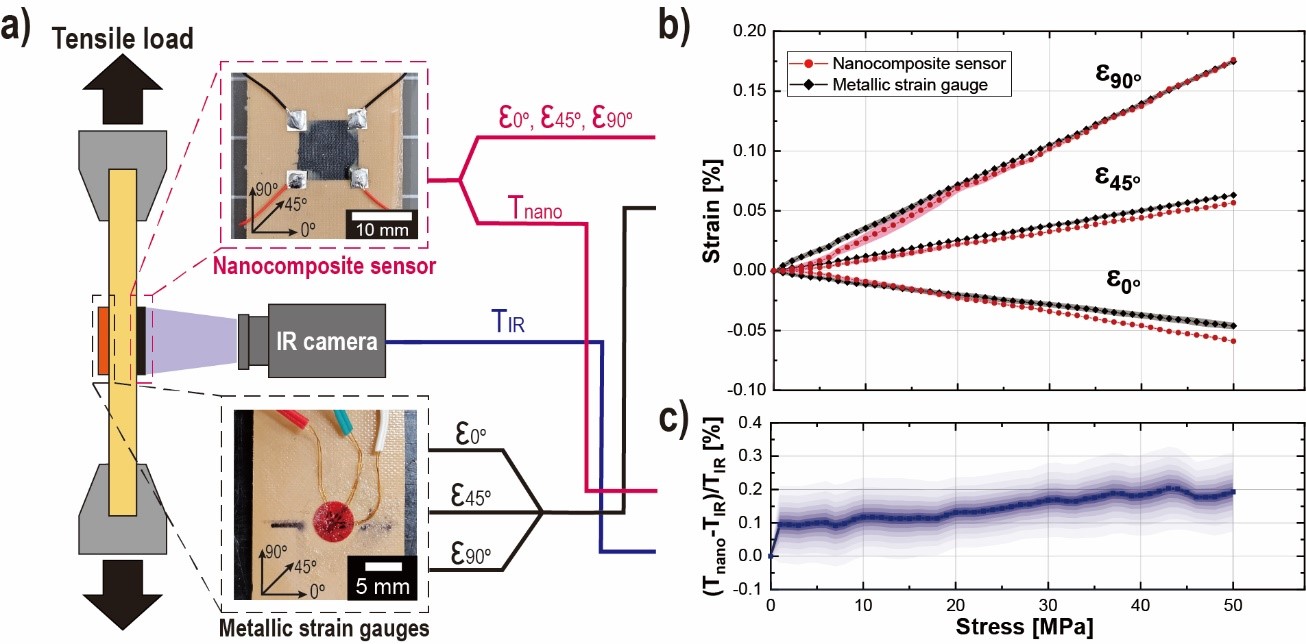

The most representative physical quantity measured for health monitoring is strain, which is detected by various strain sensors, such as metallic strain gauges and fiber Bragg grating sensors. However, conventional strain sensors only measure strain in a single direction and are also sensitive to temperature, thus presenting limitations. Owing to these characteristics, at least four sensors are required to monitor strain in all directions and temperatures of the structure, leading to complex sensor configurations and wiring.

To overcome the limitations of commercial strain sensors, the Laboratory for Advanced Materials and Processes (Advisor: Professor Jeonyoon Lee) of the Department of Aerospace Engineering at KAIST has developed a nanocomposite sensor system capable of measuring omnidirectional strain with a single sensor. This advanced sensor system can detect strain in all directions with a single nanocomposite sensor and simultaneously measure the temperature to isolate its effects. This innovation simplifies conventional systems, which typically require at least four sensors, and reduces the weight through its use of low-density nanomaterials.

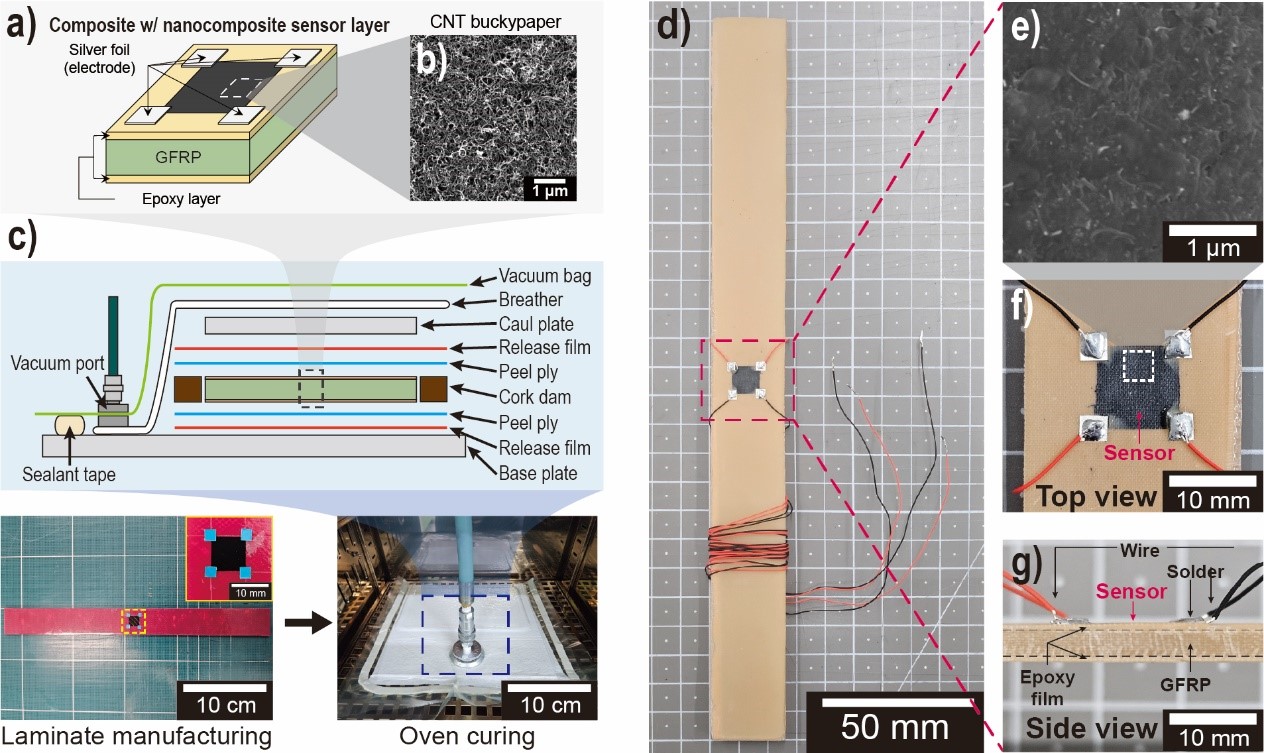

As shown in Figure 1(a), the structure of the nanocomposite sensor consists of carbon nanotube film several microns thick attached to the location of the structure to be monitored with epoxy adhesive film. The nanocomposite layer can be integrated into the surface without a significant morphology change, as shown in Figure 1(g).

Additionally, the research team confirmed the potential for developing self-monitoring composite structures capable of integrating the developed sensor system internally. The novel nanocomposite sensor presented in this study is expected to provide new dimensions to those involved in the development of simplified, ultra-lightweight next-generation structural monitoring systems.

Most Popular

High-performance and sustainable paper coating material that prevents microplastics

Read more

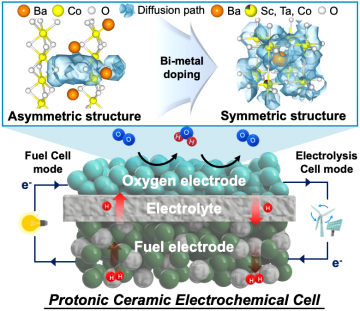

Next-generation ceramic electrochemical cells for global net-zero goals

Read more

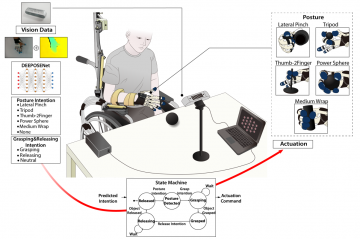

Multi-hand posture rehabilitation for stroke survivors: Rehabilitation system using vision-based intention recognition and a soft robotic glove

Read more

Impacts of new town developments on carbon sinks in the Seoul metropolitan area

Read more

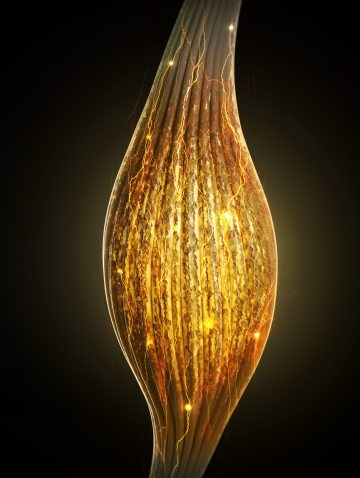

Revolutionizing strength: Hercules artificial muscles 17 times stronger than human muscles

Read more