KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Producing sound without vibration using a 3D graphene sponge

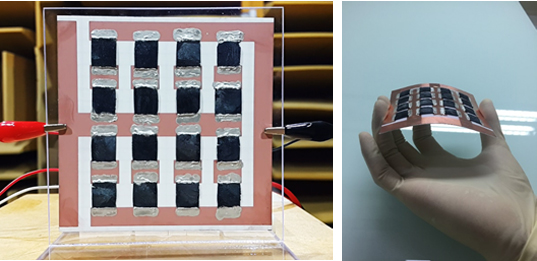

An ultra-thin, lightweight speaker is developed using a novel nanomaterial: a 3D graphene sponge. The new speaker does not vibrate to produce sound but utilizes thermal waves formed in front of a graphene conductor. This can replace many mechanical parts of conventional speakers and results in more flexible speakers that can be attached to any curved surfaces.

Article | Fall 2017

Imagine that every object or gadget around us can produce sound. The floor lamp, coffee cups, and windows can talk to us at any time to deliver information and even can collaborate to form a great 3D audio system. As for now, this is only a dream because sound is usually generated by a large voice-coil-based speaker that converts mechanical vibration into air oscillation. These speakers rely on the vibration of membranes, which means that objects or gadgets should vibrate as well or should have enough space to include complex mechanical parts.

These limitations have been tackled by Professors Jung-Woo Choi, Byungjin Cho, Sang Ouk Kim, and their research team through the development of ultra-lightweight and -thin sounding materials that can be attached to any chosen surface. Most importantly, the new speaker does not require any mechanical vibrations to produce sound. This is possible due to the thermoacoustic principle, which predicts the generation of sound from thermal waves in front of a heated foil. The thermoacoustic principle itself has a long history since 1898, and many attempts have been made to use the principle for realizing an efficient loudspeaker, formerly known as the thermophone.

Materials such as 700nm-thick platinum were used as the conductor, but the low efficiency has been a big hurdle for its practical realization. From 2008, further enhancements have been attempted using carbon nanotube (CNT) film as the conducting material. Despite its ideal characteristic as a conductor in the microscale, the low mechanical robustness of CNTs in the macroscale made it impractical as a commercial device. For example, the CNT film fabricated in a few centimeter scale can be broken even by the whispering wind, and when the film is attached to a surface, a significant amount of heat is dissipated through the surface.

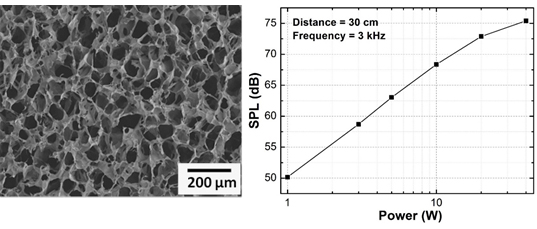

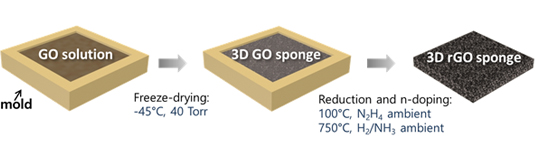

Science has now caught up to this concept largely thanks to the development of graphene, an ultra-thin carbon material that is super strong and conductive. The researchers took a different approach to minimize heat dissipation and enhance mechanical robustness through the fabrication of a 3D graphene sponge (N-doped three-dimensional reduced graphene oxide aerogel; N-rGOA). The graphene sponge has an aerogel structure, which is essentially a porous network consisting of a few layers of graphene. The porous structure minimizes the contact area with the object, thereby minimizing the heat loss. At the same time, the 3D network structure is more robust than 2D nanostructures on a macroscale, making it a self-withstanding device.

For the easy production of the new sponge structure, a simple two-step fabrication process, which includes freeze-drying and reduction/doping, was devised. Taking advantage of the facile fabrication process, the team could fabricate and analyze thermoacoustic loudspeakers with different structural properties. The analyses showed that the resistance of the proposed loudspeaker can be easily controlled, which is essential for generating a higher sound level per unit driving voltage. An array of 3D graphene loudspeaker cells was built that can withstand high input powers up to 40 W. This demonstrates that a practical thermoacoustic loudspeaker can be fabricated using the proposed mass-producible solution-based process.

Article on IEEE Spectrum: https://goo.gl/e2LMQk

Video and article on ACS Weekly PressPac: https://goo.gl/3Bj2wM

Original paper: http://pubs.acs.org/doi/pdf/10.1021/acsami.6b03618

Most Popular

When and why do graph neural networks become powerful?

Read more

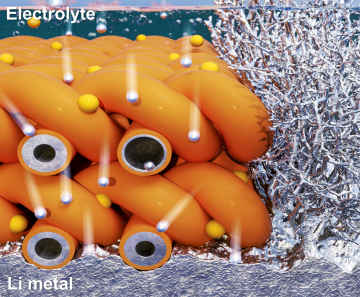

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more