KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Bio-based p-xylene oxidation into terephthalic acid by engineered Escherichia coli

Bio-based p-xylene oxidation into terephthalic acid by engineered Escherichia coli

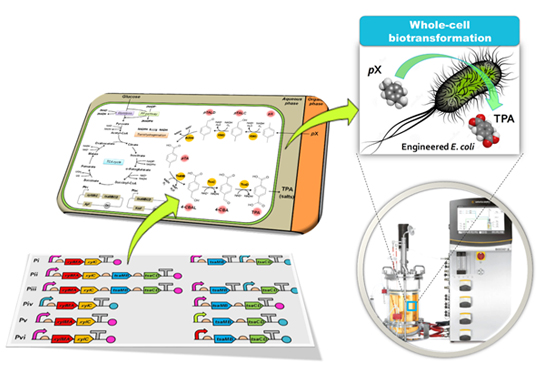

A novel and efficient biocatalysis system was created to produce terephthalic acid (TPA) from p-xylene (pX) through two-phase microbial fermentation of an engineered gut bacterium (Escherichia coli). It will make this globally-important bulk chemical available in an environmentally-friendly manner.

Article | Fall 2017

Chemicals are involved in every aspects of our daily life and play an important role in the world economy. Despite providing a variety of useful products at high productivities, the current chemical industry is inherently non-sustainable as it heavily relies on non-renewable petroleum resources and often environmentally-damaging production processes. For these reasons, biocatalysis has recently attracted a great deal of attention as a green solution to chemical production.

Distinguished Professor Sang Yup Lee and his team have established an efficient biocatalysis system to produce TPA from pX. This biocatalysis system represents a greener and more efficient alternative to the traditional petro-chemical methods for TPA production.

Prof. Lee’s team exploited a metabolic engineering and synthetic biology approach to develop a recombinant micro-organism that can oxidize pX to TPA by microbial fermentation. TPA is a globally-important commodity chemical necessary for manufacturing polyethylene terephthalate (PET), which is used to make plastic bottles, clothing fibers, films, and many others. Currently, TPA is produced from pX oxidation through an important industrial chemical process known as the Amoco process, which accounts for nearly all TPA production worldwide with a typical TPA yield of over 95 mol%. However, this petroleum process has such drawbacks as intensive energy requirement at high temperature and pressure, usage of heavy metal catalysts, and unavoidable byproduct formation of 4-carboxybenzaldehyde.

Inspired by several earlier studies to discover and isolate certain wild-type bacterial strains from nature that are able to convert pX to TPA, the research team rationally designed and constructed a synthetic metabolic pathway. Incorporation of the xylene degradation pathway of the Pseudomonas putida strain and p-toluene sulfonate pathway of a Comamonas testosteroni strain successfully produced TPA from pX in small-scale cultures; however, p-toluate (pTA) was found to be a major byproduct. The newly constructed pathway was then optimized to yield a final E. coli strain that can produce a higher titer of TPA by eliminating pTA production.

Using the best-performing strain, Prof. Lee and his team designed an elegant two-phase (aqueous/organic) fermentation system for TPA production on a larger scale. The two-phase design was adopted to overcome problems seen through the use of volatile, insoluble, and toxic pX for feeding the bacteria to produce TPA. Because strong agitation and aeration are required for cell growth in fermenters, oleyl alcohol (OA) was used as the organic carrier of pX. The low-cost, phase stable OA is biocompatible with E. coli, which is suitable for use in an aqueous culture medium. The researchers tested various fermentation conditions, including the quantity and rate of pX feeding, cell densities and oxygen control. Through process optimization, 13.3 g of TPA from 8.8 g of pX was produced, which is the highest yield of TPA, with an extraordinary yield of 97 mol%.

The team has developed a microbial biotechnology application which is reportedly the first successful example of bio-based production of TPA from pX by microbial fermentation of engineered E. coli. This bio-based TPA technology presents several advantages over traditional petro-chemical processes, such as ambient reaction temperature and pressure, no use of heavy metals or other toxic chemicals, removable byproduct formation, and most importantly, 100% environmental compatibility.

The team further proposes that since pX can be derived from biomass (such as by using a zeolite catalyst), TPA can now be produced without fossil fuel resources but rather by using the E. coli system developed here. They state that future research should include the development of a new pathway and engineered strain that can produce TPA by direct one-step fermentation from carbohydrates such as glucose.

This research was published in Nature Communications (DOI:10.1038/ncomms15689) on May 31, 2017 and was also highlighted by a number of press media.

https://www.sciencedaily.com/releases/2017/06/170605121323.htm

https://phys.org/news/2017-06-bio-based-p-xylene-oxidation-terephthalic-acid.html

https://www.eurekalert.org/pub_releases/2017-06/tkai-bpo060417.php

http://www.koreaherald.com/view.php?ud=20170604000158

http://www.sciencenewsline.com/news/2017060515370080.html

Most Popular

When and why do graph neural networks become powerful?

Read more

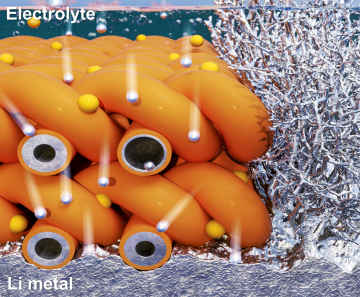

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more