KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Highly stretchable, durable, and manufacturable tactile sensor for robotic skin

Highly stretchable, durable, and manufacturable tactile sensor for robotic skin

A novel soft tactile sensor, which is highly stretchable, durable, and manufacturable, is developed to make robotic skin a reality in the future. Since this sensor used a highly conformable force-sensing nanocomposite as a sensing material, the mechanical property of this material is similar to that of human skin. Furthermore, this sensor employed only a few electrodes located at the boundary of the sensor to collect tactile information across the entire sensor surface. This novel approach ensures durability because sensing electrodes can be protected. In addition, complicated fabrication can be avoided, which facilitates manufacturing.

Article | Fall 2017

“Sense of touch” is an essential human sensation guiding safe and dexterous interactions with the surrounding environment. Without tactile information, humans cannot manipulate an object manually or walk naturally. The sensing technology to provide robot with the sense of touch requires certain level of accuracy, robustness, and softness which are needed in future robot applications, for instance, rehabilitation robots, wearable devices, surgical robots, humanoids.

As the importance of soft tactile sensors has increased, many researchers have demonstrated human soft and versatile tactile sensors that function like human skin. However, practically useful tactile sensors have not yet been presented, particularly for practical situations where frequent abrasive contact occurs or where contact information needs to be measured from complex-shaped surfaces. Previously developed tactile sensors are too expensive to implement or fragile due to a thin-film-based fabrication process.

Professor Jung Kim and Professor Inkyu Park collaborated to explore a strategy for developing practically useful tactile sensor for robotic skin through a soft nanocomposite and a tomographic sensing approach. They pursued practical utilization of soft nanocomposites as a strain mapping sensor in tactile sensors. Two important constraints that the professors needed to account for were that artificial skins must be robust to various contact conditions and that the fabrication process for large three dimensional surfaces must be cost-effective in order to be utilized.

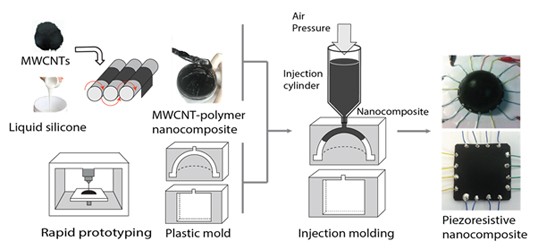

Professor Inkyu Park’s team fabricated highly soft nanocomposite using carbon nanotubes and silicone rubber. Their approach focused on developing a low-cost sensing material while providing acceptable sensing performance. To realize this concept, multi-walled carbon nanotubes (MWCNTs) were mixed with silicone rubber paste. Figure 1 shows a schematic diagram of the fabrication process. MWCNTs and liquid silicone are dispersed by shear milling. The resulting paste can be applied to a variety of manufacturing methods such as injection molding, screen printing, or even painting on elastic fabric [1]. These manufacturing methods can be used to make large three-dimensionally-shaped nanocomposites, such as a hemisphere or planar sheet, as shown in Figure 1. This nanocomposite shows piezoresistance, which means that the electrical resistivity of the material changes when it deforms due to external forces.

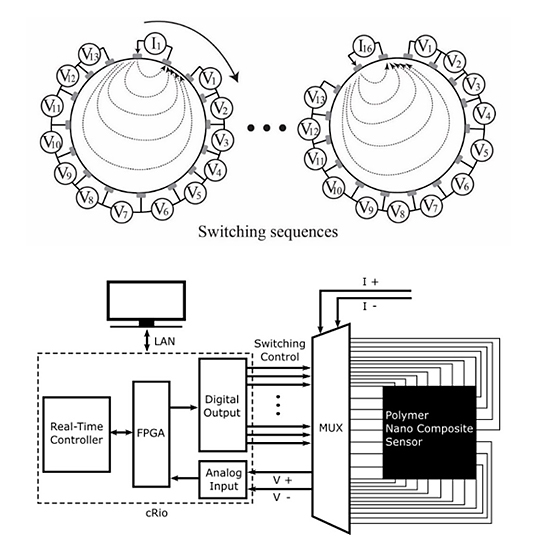

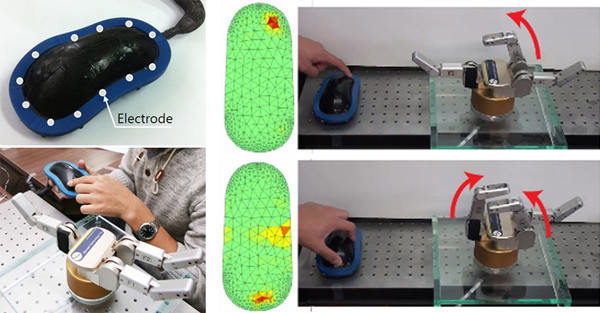

At the same time, Professor Jung Kim’s team developed a tactile data acquisition method using fewer electrodes. Conventionally, a large number of electrodes are needed to acquire tactile data because every individual sensing element is connected to each electrode. Although there are some smart approaches to reduce the number of electrodes, this was still a critical problem when developing soft and stretchable tactile sensors. To solve this, Professor Jung Kim’s research team suggested an alternative approach to acquire tactile data. They adopted the tomographic sensing method, which was originally developed for medical image acquisition. The working principle of this imaging method is shown in Figure 2 (top). First, an electrical current is induced to one boundary of the conductive medium. Following the electrical current, an electrical potential field is formed in the conductive medium. This potential field is measured from the other boundaries. After the measurements have been taken, the electrical current is induced to another location, and the changed potential field is measured. This measurement procedure is completed in 0.01 seconds through the high-speed controller circuit shown in Figure 2 (bottom).

The key challenges were optimizing and integrating soft nanocomposite and the tomographic sensing method to implement the three-dimensionally-shaped soft tactile sensor while ensuring durability. The mechanical and electrical properties of the nanocomposite were modified to reduce contact resistance between the electrodes and the nanocomposite. To enhance durability, electrode locations were also optimized to avoid severe contact force.

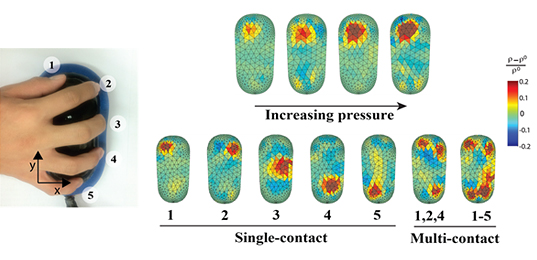

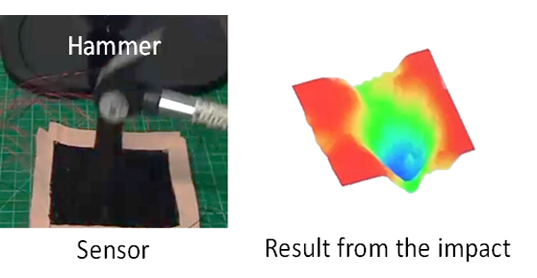

To demonstrate the soft tactile sensor, a mouse-shaped human robot tactile interface was developed, as shown in Figure 3. The developed interface could have both single and multi-touches of the user as well as the level of the pressure. This denotes that the proposed approach could be used to make three-dimensional-shaped tactile sensor with low-cost material and a simple fabrication method. Furthermore, the proposed sensor was durable, even with a strong impact from a hammer, as shown in Figure 4. This means that the proposed soft tactile sensor has great potential for shock absorption and impact monitoring at the same time.

Professor Kim and Professor Park said, “This soft tactile sensor can be attached to human skin for medical and wearable applications in the future and will provide invaluable contact information for the whole body. In addition, this research combined multidisciplinary knowledge from nanocomposite and computer-assisted tomographic imaging to develop a new tactile sensor.” Dr. Hyosang Lee who was the main developer of this research added, “There was always a need of cheap and practically useful tactile sensors in many robot applications. I hope this technology can accelerate artificial intelligence of robots by providing abundant tactile data through low-cost mass production of piezoresistive material as well as standardization of the sensing method.”

The result of the soft tactile sensor was reported in Scientific Reports (39837, 2017, DOI: 10.1038/srep39837) under the title “Soft Nanocomposite Based Multipoint, Multi-directional Strain Mapping Sensor Using Anisotropic Electrical Impedance Tomography” [2].

For demonstration video, please check out:

Mouse interface: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5264388/bin/srep39837-s2.mov

Tactile pad: https://youtu.be/usbr41z_ilk

[1] Lee, H., Cho, J. and Kim, J. 2016. Printable skin adhesive stretch sensor for measuring multi-axis human joint angles. Robotics and Automation (ICRA), 2016 IEEE International Conference on (2016), 4975–4980.

[2] Lee, H., Kwon, D., Cho, H., Park, I. and Kim, J. 2017. Soft Nanocomposite Based Multi-point, Multi-directional Strain Mapping Sensor Using Anisotropic Electrical Impedance Tomography. Scientific Reports. 7, (2017).

Most Popular

When and why do graph neural networks become powerful?

Read more

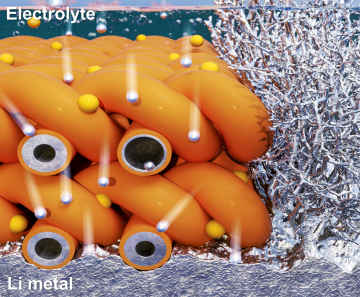

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more