KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Air-processable and scalable formation of high-quality organic films on a water substrate via a spontaneous spreading phenomenon

Air-processable and scalable formation of high-quality organic films on a water substrate via a spontaneous spreading phenomenon

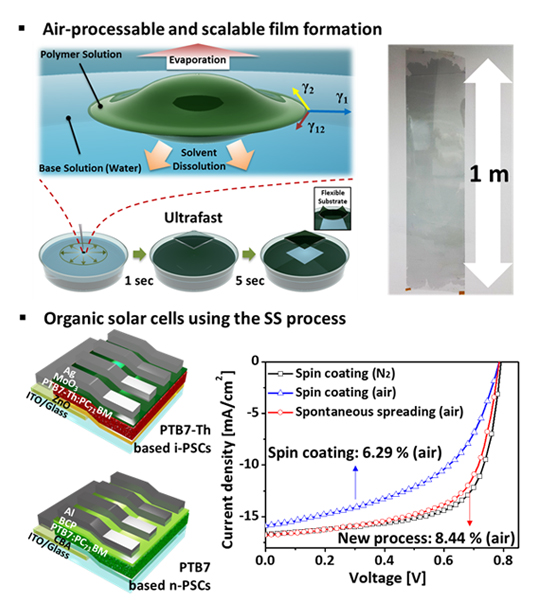

A versatile ultrafast deposition technique was developed to form ambient air-processable and high-quality organic bulk heterojunction films on an aqueous substrate via spontaneous spreading flow. Highly efficient polymer solar cells were fabricated using this technique.

Article | Fall 2016

Organic solar cells (OSCs) are garnering attention as a next-generation energy source because of their transparency, light weight, flexibility, and potentially low-cost manufacturing processes, all of which offer fascinating application possibilities in portable electronic devices such as tablets, laptops, and cellular phones, as well as building-integrated photovoltaics (BIPV).

Despite impressive power conversion efficiencies (PCEs) of over 11% to date, the commercial viability of OSCs has been delayed because of limited options for producing high-quality organic films on an industrial scale while maintaining such high PCEs.

Recently, a research team led by Prof. Jung-Yong Lee in the Graduate School of EEWS (Energy, Environment, Water, and Sustainability) developed a novel technique to form organic films on a water surface via “spontaneous spreading flow.” This spreading phenomenon, called the Marangoni effect, which occurs because the surface tension difference between water and a second fluid), initiates fast mass transportation at the interface. The effect was thoroughly studied by an Italian physicist Carlo Marangoni in his doctoral dissertation in 1865. A common example of this Marangoni effect is when a single drop of detergent drips onto a water surface, ground pepper floating on the water surface is spontaneously swept away toward the edge of the water container because water has a higher surface tension than that of the detergent.

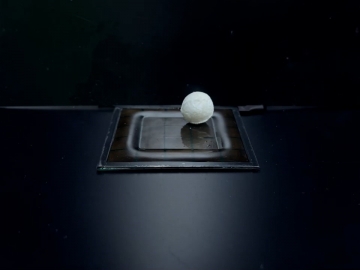

By applying the above-mentioned phenomenon, Prof. Lee’s research team developed an ingenious technique for forming thin organic films within a few seconds, named the “spontaneous spreading (SS) process.” When a drop of solution containing organic materials lands on the water’s surface, the solution quickly spreads over the surface. Dissolution and evaporation of solvents result in a thin solid film on the water due to the films’ hydrophobicity. This thin film can be transferred to any substrates via stamping the substrate on to it. A prominent advantage of the SS process is in the rapid formation of high-quality films under ambient conditions where the rapid drying process effectively prevents the adsorption of oxygen, which tends to degrade organic films. The research team fabricated OSCs from a polymer mixture and fullerene by using the proposed process in air. Despite the presence of air and water, the OSCs exhibited excellent performance of 8.44% PCE, which is comparable to that of the devices fabricated by a spin-coating process under low-oxygen and low-humidity conditions. In addition, the research team also demonstrated the transfer of large-area organic films (100 cm × 25 cm) with excellent uniformity via the ultrafast and versatile transfer technique, which is perfectly compatible with a roll-to-roll (R2R) processing system.

An R2R process is an industrial manufacturing technology that allows continuous fabrication of electronic devices on a roll of flexible substrates such as plastic or metal foils, while the substrates move between the rolls. Therefore, the R2R manufacturing process is considered a promising technology for OSC production. A slot-die coating process is a well-established technique for the R2R processes allowing for the high-throughput production of OSCs at low cost; however, high-film quality and air-processability may not be guaranteed. In this regard, the novel SS process can be used for the commercialization of OSCs, with low material consumption, fast drying time, and, most importantly, low fabrication cost.

“We believe that the present study provides an alternative route toward facile fabrication of OSCs because the approach ensures the ultrafast and scalable formation of high-quality polymer films in large areas. We anticipate efficient and successful commercialization of OSCs in the near future,” commented Prof. Lee.

An article on this research (entitled “Ultrafast formation of air-processable and high quality polymer films on an aqueous substrate”) was published in August 2016 in Nature Communications.

Reference: J. Noh, S. Jeong, and J. –Y. Lee, Ultrafast formation of air-processable and high quality polymer films on an aqueous substrate. Nat. Comm. DOI: 10.1038/ncomms12374 (2016).

Additional link for more information:

http:// (Article)

http://adec.kaist.ac.kr/

Most Popular

When and why do graph neural networks become powerful?

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

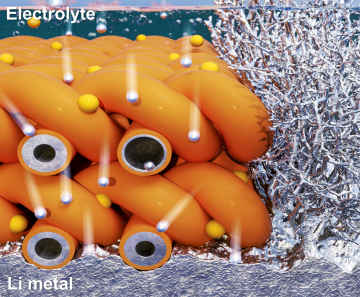

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more