KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Two-dimensional ceramic matrix nanocomposite reinforced by nanomaterial for high-temperature applications

Two-dimensional ceramic matrix nanocomposite reinforced by nanomaterial for high-temperature applications

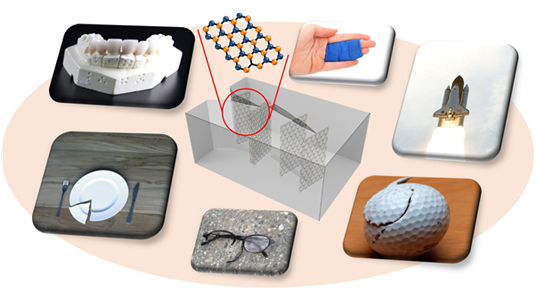

Hexagonal boron nitride nanoplatelets (BNNP)-reinforced ceramic matrix nanocomposites with superior mechanical properties for aerospace or prostheses applications are firstly developed.

Article | Fall 2016

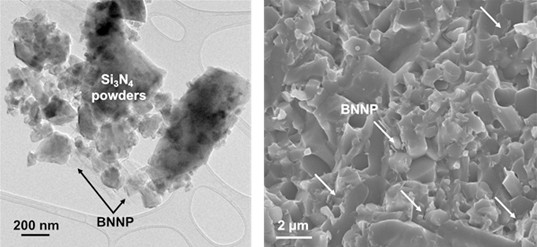

Prof. Soon Hyung Hong (Department of Material Science and Engineering) and Prof. Ho Jin Ryu (Department of Nuclear and Quantum Engineering) firstly developed a technology to fabricate hexagonal boron nitride nanoplatelets (BNNP)-reinforced ceramic nanocomposites.

Ceramic materials can be used in wide structural application areas; however, they are inherently brittle due to low fracture toughness and impact resistance. Therefore, it is necessary to enhance the fracture toughness of the ceramic materials based on composite toughening principles using various types of reinforcements.

Graphene, a well-known two-dimensional nanomaterial, has been widely studied as a reinforcement for ceramic materials due to its superior mechanical properties. However, it is not suitable for substrate application for electrical devices because of its high electrical conductivity. Furthermore, its low thermal stability in an oxidizing atmosphere and inherently black color have limited its applications in high-temperature and artificial tooth applications.

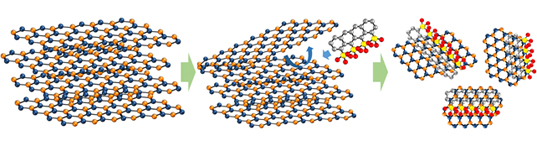

BNNP is also known as a two-dimensional nanomaterial having a hexagonal honeycomb nanostructure consisting of boron and nitrogen atoms. The BNNP has superior mechanical properties, transparency, biocompatibility, and high thermal stability up to 1000℃ in oxidizing atmosphere, all of which make it applicable as a reinforcement for high-temperature structural materials and artificial tooth applications. Due to its superior mechanical properties and unique structure, BNNP has been considered a promising reinforcement for structural ceramics; however, it is not as widely used as graphene because of the difficulties associated with its fabrication process.

The collaborating professors, Hong and Ryu, used the “high-energy ball-milling process” to fabricate thin-walled BNNP. The well-known ball-milling process supplies energy to mix and/or refine microstructures of materials through repeated collisions of balls within a rotating jar. The research group developed a novel process to fabricate BNNP by exfoliating hexagonal boron nitride with the addition of controlling agents using the high-energy milling process.

Prof. Hong’s group reported that if 2 weight % BNNPs are homogeneously dispersed in a silicon nitride matrix, the strength can be enhanced by 10%, fracture toughness can be improved by 20%, and wear resistance can be improved by 30%. Based on these outstanding results, the strengthening and toughening effects with additional enhancement in high-temperature stability by using BNNP reinforcement would extend the applications of ceramic composite materials into aerospace components, artificial tooth material, substrates for ICT devices, etc.

An article on this research entitled “Enhanced of toughness and wear resistance in boron nitride nanoplatelet (BNNP) reinforced Si3N4 nanocomposites” was published June 8th, 2016 in Scientific Reports (http://dx.doi.org/10.1038/srep27609).

Most Popular

When and why do graph neural networks become powerful?

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Oxynizer: Non-electric oxygen generator for developing countries

Read more