KAIST

BREAKTHROUGHS

Research Webzine of the KAIST College of Engineering since 2014

Spring 2025 Vol. 24Coatable Electronic Skin: E-skin can be coated on three-dimensional surfaces

Coatable Electronic Skin: E-skin can be coated on three-dimensional surfaces

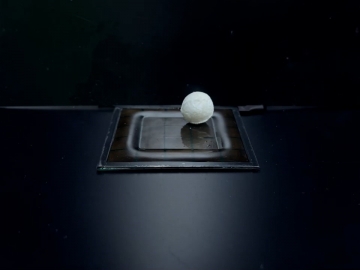

An electronic skin was created that can be coated on three-dimensional surfaces and can distinguish mechanical stimuli.

Article | Spring 2019

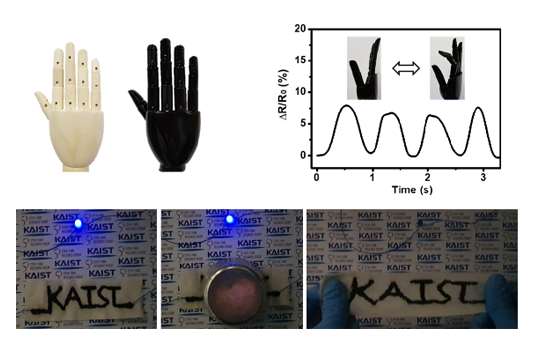

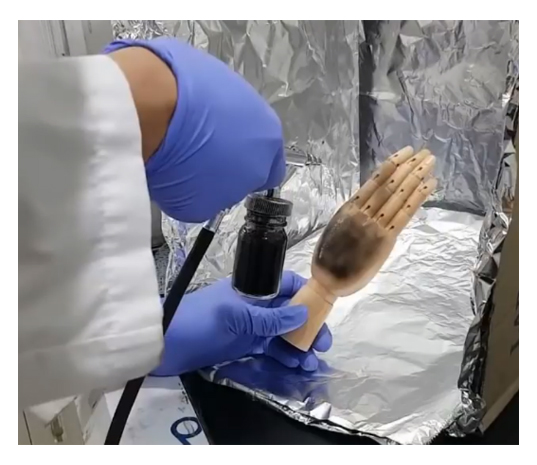

Recently, electronic skin (e-skin) research has been actively carried out to mimic human-level tactile sense for various applications. However, previously reported e-skins had several issues. One of the major problems is the difficulty in coating e-skin on complex surfaces. In order for e-skin to precisely measure the stimulus, its conformal coating on three-dimensional surfaces is essential. To overcome this issue, the research team utilized the solution process to fabricate e-skin. The solution process enables e-skin to be manufactured using various conventional printing methods such as spray coating and nozzle printing. Using these printing techniques, e-skin can be uniformly coated on any kind of three-dimensional surface.

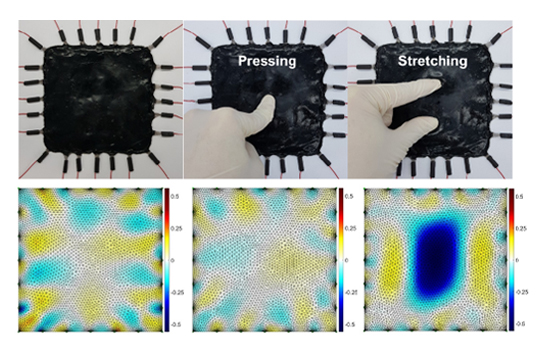

The developed e-skin can also distinguish mechanical stimulus analogous to human skin. The structure of the e-skin was designed to be deformed differently according to the respective pressure and the tensile strain applied. Under the applied tensile strain, the conducting pathways change largely, thereby increasing the resistance on a considerable scale. On the other hand, under the applied normal pressure, the change of the conducting pathway is minimized, and therefore, there is a negligible change in resistance. Due to this working mechanism, the developed e-skin is highly sensitive to strain, but insensitive to pressure.

The research team spatially mapped the local strain without the use of a patterned electrode array, instead using an electrical impedance tomography (EIT) method. By using EIT, it is possible to minimize the number of electrodes, enabling e-skin to be more feasible for use on three-dimensional surfaces.

Professor Park said, “Developed e-skin can be mass-produced at low cost, and easily coated on complex three-dimensional surfaces”, and “It is a fundamental technology which can be a step closer to the commercialization of e-skin”.

The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications (DOI: 10.1021/acsnano.8b03488)” was published in the August 2018 issue of ACS Nano as the cover article.

Journal Reference:

Jinwon Oh, Jun Chang Yang, Jin-Oh Kim, Hyunkyu Park, Se Young Kwon, Serin Lee, Joo Yong Sim, Hyun Woo Oh, Jung Kim, and Steve Park. Pressure Insensitive Strain Sensor with Facile Solution-Based Process for Tactile Sensing Applications. ACS Nano, 2018; 12 (8): 7546 DOI: 10.1021/acsnano.8b03488

Most Popular

When and why do graph neural networks become powerful?

Read more

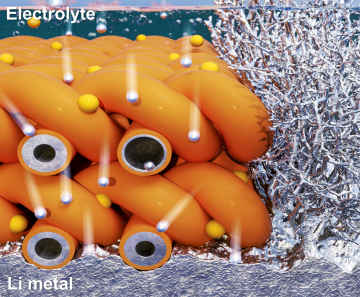

Extending the lifespan of next-generation lithium metal batteries with water

Read more

Professor Ki-Uk Kyung’s research team develops soft shape-morphing actuator capable of rapid 3D transformations

Read more

Smart Warnings: LLM-enabled personalized driver assistance

Read more

Development of a nanoparticle supercrystal fabrication method using linker-mediated covalent bonding reactions

Read more